Image Source: pexels.com

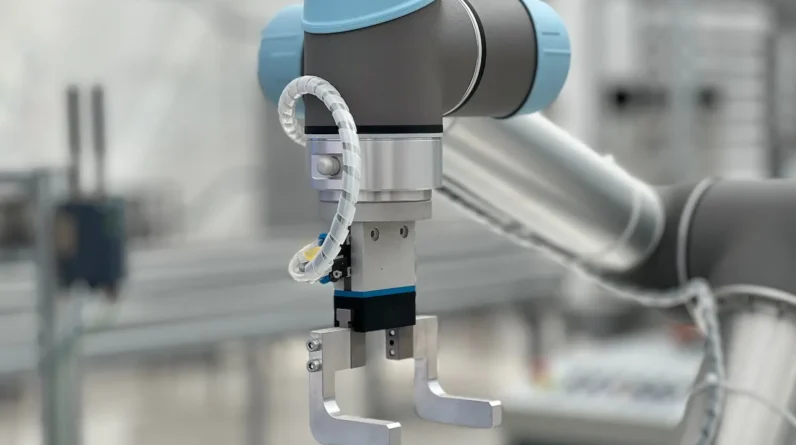

The UR5 robot is a cutting-edge robotic arm that has been developed to assist businesses in various industries with boosting efficiency and productivity. This versatile robotic arm can be used for various tasks, from assembly and packaging to welding and material handling. By utilizing the UR5, companies can reduce operational costs while increasing their output.

The UR5’s user-friendly interface makes it an excellent investment for any business looking to remain competitive in today’s market. While companies can utilize the UR5 robot in numerous ways, this article will focus on the methods for enhancing productivity with the UR5 in different industries.

Automating tasks

Automating tasks is one of the primary benefits of utilizing the UR5 robotic arm. The robot can be programmed to perform repetitive and mundane tasks, freeing employees to focus on more essential duties. It allows for faster production times and an overall increase in efficiency. Since it can work continuously without fatigue or distractions, it can even help reduce errors caused by human workers.

Automation also helps improve workplace safety by reducing the chance of accidents. By replacing dangerous tasks with automated ones, employers can provide a safer working environment for their staff while optimizing their output.

Assembly

The UR5’s precision and repeatability make it an ideal tool for assembly-related tasks in many industries. The robot’s high accuracy and repeatability allow it to perform tasks precisely, which can be especially beneficial in industries like electronics manufacturing, where exact parts are often required.

In addition, its lightweight design and intuitive programming allow for a wide range of uses, from assembling small pieces to more significant components. The UR5 is also highly reliable and requires minimal maintenance, ensuring that production times remain consistent without any unexpected downtime. It can also easily be integrated into existing systems, making setting up assembly lines much more efficient.

Material Handling

Material handling is another area where the UR5 excels. Its robust design and programmable motion control make it perfect for moving heavy loads, such as boxes or pallets, without extra support or human resources. It helps significantly reduce labor costs and increases output. The UR5 can also be programmed to handle specific items, allowing faster and more accurate handling.

Its ability to work in tight spaces makes it ideal for material handling tasks that require precise movements in hard-to-reach places. Robotic arms also help reduce the chance of workplace injuries, as they can lift heavier objects without putting strain on human workers.

Welding

Welding is an essential part of many businesses, especially those in the automotive and construction industries. The UR5 robotic arm is an excellent tool for welding jobs because it can perform this task with precision and accuracy, eliminating potential errors caused by human workers. It helps to ensure that welds are solid and durable while reducing overall costs associated with welding projects.

Its lightweight design makes it easy to move from one place to another, making it perfect for welding jobs that require delicate work in hard-to-reach places. In addition, the UR5 is highly reliable and requires minimal maintenance, allowing welders to focus on their projects without worrying about repairs or downtime.

Packaging

The UR5 robotic arm is an excellent tool for packaging tasks. Its accuracy and repeatability make it ideal for handling small components precisely, while its lightweight design allows easy movement from one place to another. It helps businesses save time and money by reducing labor costs associated with packaging tasks.

The robot can also be programmed to handle specific items, allowing faster and more accurate handling of products without human assistance. Its intuitive programming also makes it easy to integrate into existing systems, allowing companies to quickly get their packaging operations up and running with minimal setup time.

Inspection

The UR5 robotic arm is an excellent tool for inspecting parts and products. Its accuracy and repeatability make it perfect for accurately identifying defects or imperfections in materials, increasing product reliability while reducing wasted materials.

It can also be programmed to do simple tasks such as counting objects or comparing them against standards. It helps businesses save time and money by ensuring quality control without relying on human labor. The UR5’s intuitive programming also makes it incredibly easy to integrate into existing systems, simplifying the inspection process for companies.

Document handling

The UR5’s lightweight design and intuitive programming make it an ideal tool for document-handling tasks. Its accuracy and repeatability allow it to handle documents efficiently, reducing potential errors while saving time and money.

The robot can also be programmed to do specific tasks such as sorting, scanning, or folding paper. It helps businesses save time and labor costs by automating tedious document-handling tasks that would otherwise be done by hand. Its ability to work in tight spaces makes it perfect for workplaces with limited space.

Also Read: How You Can Use AI to Improve Your Online Advertising Results